1. Structure and working principle of precision air conditioner

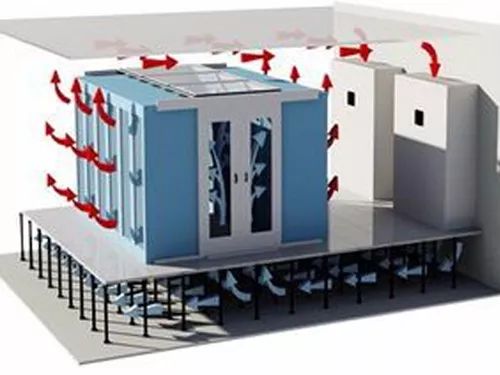

0 Precision air conditioners are mainly composed of compressors, condensers, expansion valves and evaporators. Generally speaking, the cooling process of the air conditioner is: the compressor compresses the refrigerant gas that has absorbed heat energy after passing through the evaporator into a high-pressure gas, and then sends it to the condenser of the outdoor unit; the condenser heats the high-temperature and high-pressure gas through the fan to the surrounding Released in the air, the high-temperature and high-pressure gas refrigerant is recondensed into a liquid, and then sent to the expansion valve; the expansion valve cools the liquid refrigerant sent from the condenser pipe to a mixed liquid and gas refrigerant, and then sent to Go to the evaporator circuit; the evaporator re-evaporates the liquid and gas refrigerant into the gaseous refrigerant by absorbing the heat in the equipment room environment, and then sends it back to the compressor, repeating the previous process.

2. Maintenance of precision air conditioner in computer room

In addition to the compressor, condenser, expansion valve, and evaporator introduced earlier, the composition of precision air conditioners also includes: fans, air filters, humidifiers, heaters, drains, etc. The management and maintenance of air conditioners are mainly for the maintenance of the above components. The following are some of our maintenance experience and learning experience for the precision air conditioners dedicated to the computer room in our daily work.

1. Maintenance of control system

For the maintenance personnel of the air-conditioning system, the first step in the inspection is to see whether the air-conditioning system is operating normally, so we first need to do some of the following work.

1) Check whether the functions and parameters of the air conditioning system are normal from the display screen of the air conditioning system;

2) If there is an alarm, check the alarm record and analyze the cause of the alarm;

3) Check whether the working status of temperature and humidity sensors is normal;

4) Be aware of the operating parameters of the compressor and humidifier, especially at the first inspection every morning, compare the operating parameters of the compressor the night before with the previous parameters of the same period, To see if there is a big change, according to the parameter change, you can judge whether there is a big change in the operating conditions of the computer equipment in the computer room, so as to reasonably allocate the number of operation of the air conditioning system and adjust the operating parameters of the air conditioner. Of course, at present, some older air-conditioning systems are not able to read out these parameters, which requires the staff on duty at night to observe and record more.

3. Roving inspection and maintenance of compressor

1) Listening—using the method of listening to sound, the operation of the compressor can be judged more accurately. Because when the compressor is running, its sound should be even and rhythmic. If its sound loses the rhythm and there is uneven noise, it means that the internal parts of the compressor or the working conditions of the cylinder have changed abnormally.

2) Touch—The method of touching by hand can know the degree of heat generation, and can roughly judge whether the compressor is operated under a specified pressure and a specified temperature.

4) Quantity—mainly to measure the current and suction and discharge pressure when the compressor is running, which can accurately judge the operation status of the compressor.

Of course, we also need to check the high and low pressure protection switch, drying filter and other accessories for the compressor.

4. Circuit inspection and maintenance of the condenser

1) The maintenance of the professional air-conditioning condenser is equivalent to the maintenance of the outdoor unit of the air-conditioning, so we first need to check the fixing of the condenser to see if there are any signs of looseness on the fixing parts of the condenser, so as not to cause refrigerant pipe and outdoor damage.

2) Check whether the refrigerant pipeline is damaged (of course, it can also be judged whether the refrigerant pipeline is damaged from the working status of the compressor and some other performance parameters), check the insulation status of the refrigerant pipeline, especially in the winter in the northern region, this is An important task, if the ambient temperature is too low and the insulation of the refrigerant pipeline is not good, it will have a certain impact on the normal operation of the air conditioning system.

3) Check the operating status of the fan: mainly check the working conditions of the fan's bearings, base, motor, etc., whether there is abnormal vibration when the fan is running, and whether the fan of the fan is also on the same plane when it is rotating.

4) Check whether there is any debris under the condenser that affects the smoothness of the air channel, which affects the condensation effect of the condenser; check whether the fins of the condenser are damaged.

5) Check whether the current when the condenser is working is normal, and the working current can also further determine whether the fan's working condition is normal.

6) Check whether the speed control switch is normal. The condenser of a general air conditioner has two speed control switches, which are divided into temperature and pressure speed control. Now the relatively new control technology uses dual pressure speed control, so we are checking the speed control When switching, it is mainly to see whether the speed control switch can normally control the start and stop of the fan within the specified pressure range.

5. Circuit inspection and maintenance of evaporator and expansion valve

The maintenance of the evaporator and expansion valve is mainly to check whether the evaporator coil is clean, whether there is frost, and whether the drainage of the evaporator drain tray is unobstructed, such as serious frost on the evaporator coil or compression When the temperature on the coil is high when the machine is running (normally, the temperature of the evaporator coil should be about 10 ℃ lower than the ambient temperature), you should check the high and low pressure of the compressor. If the pressure is normal, you should consider Whether the opening amount of the expansion valve is appropriate. Of course, this phenomenon may also be caused by other environmental reasons, such as insufficient cooling capacity of the air conditioner, too slow wind speed caused by fan failure and so on.

6. Inspection and maintenance of humidification system

1) Due to the different air environment in each place, the use and impact of the humidifier are also different, but the same thing we do in daily maintenance work is to observe whether there is precipitated matter in the tank, if there is any Flushing, because the humidification tank of the air conditioner is generally electrode type, if there is too much sediment and it is not washed in time, it is easy to scale on the electrode and affect the service life of the humidification tank. Of course, the electrodes of some humidification tanks can now be replaced.

2) Check whether the working conditions of the water supply and drainage solenoid valves are normal. During the operation of the humidification system, there is a situation that often occurs, but it is not easy to judge, that is, when the air conditioning system is working normally, there is a certain period of water outage for some reason, and then the water supply is restored. The humidification tank cannot be filled with water normally. There are many reasons for this phenomenon, and directly resetting the humidification system in the control system of most air conditioners usually cannot solve the problem; The main reason for this phenomenon is that the air after the water stop enters the front end of the inlet solenoid valve, which has a certain effect on the normal opening of the inlet solenoid valve. Open the water inlet and drain the air. The second is to turn off the power of the humidification system and re-energize the solenoid valve to basically solve this type of problem.

3) Check whether the drainage pipe of the humidification tank is unblocked, so that it can be carried out smoothly when it is necessary to drain and repair the humidification tank.

4) Check whether the steam pipeline is smooth, and ensure that the water vapor of the humidification system can humidify the computer equipment normally.

5) Check whether the water leak detector is normal, which is an important part for the humidification system, because if the drainage pipe is not smooth, it is easy to form a water leakage situation. If the water leak detector is not normal, it is prone to accidents. Of course, for the general air-conditioning system, the water leak detector is an option. If the air-conditioning system is not equipped with a water leak detector, then we should pay more attention to monitoring whether the drainage pipe is unobstructed, and at the same time, we must also do maintenance work on the waterproof wall of the computer room.

7. Circuit inspection and maintenance of air circulation system

For the air circulation system, we mainly consider the filters, fans, air barriers and air channels to the computer equipment of the air conditioning system. Therefore, we must do some of the following in our daily maintenance work:

1) The equipment in the computer room often has the phenomenon of equipment movement, and the movement of the equipment is generally not completed by the maintenance personnel of the air-conditioning equipment. Therefore, we should check the airflow in the equipment room in time after the equipment is moved to see if there is a short circuit in the airflow The phenomenon occurs, and at the same time, is there a situation where the air supply resistance is too large at the location of the new equipment. If any of the above phenomena should be adjusted in time, if the adjustment is not possible, it should be recommended to move the device to a new suitable location.

2) Check whether the air conditioner filter is clean, if it is dirty, it should be replaced or cleaned in time.

3) Check the operation status of the fan: mainly check the tightening and balance of the components of the fan, check the bearings, belts, resonance, etc .; the fan should be checked very carefully, because the heat exchange process of the evaporator is mainly caused by the fan Under the effect of, the fast-flowing airflow is completed through the low-temperature evaporator coil, so that the air conditioner achieves the cooling effect, so the normal operation of the fan is the final manifestation of the normal operation of the air-conditioning system; of course, the most important for the fan It is the motor, so we should first check the condition of the belt and whether the main and follower wheels are on the same side in daily maintenance; the degree of tightness of the belt adjustment should be appropriate, too loose and easy to slip, too tight on the wear of the belt too Fast, the tightness of the belt has a relatively large relationship with the external demand for static pressure. Of course, this adjustment is carried out within the scope of the control of the air conditioning system; now some of the more advanced air conditioning systems use integrated fans. Solved the problem of belt adjustment.

4) Measure the running current of the motor to see if it is within the specified range. According to the measured parameters, you can also determine whether the motor is operating normally.

5) Measure the temperature and humidity values and compare with the values displayed on the panel. If there is a large error, the temperature and humidity should be corrected. If the error is too large, the cause should be analyzed. There are two reasons for this situation from our peacekeeping experience: one is the failure of the control board, and the other is that the temperature and humidity probes need to be replaced.

6) Checking the closure of the air barrier is for the air conditioners that have been shut down. This is also a link that we easily miss in our daily maintenance work, but it is also a more important link, because an air conditioner stops operating. The temperature and humidity probes of the air barrier are not closed, but the temperature and humidity of the outlet of other air conditioners are detected. The next time the air conditioner is turned on, the control system will control the operation of the air conditioner system according to the previously detected parameters. At this time, the air-conditioning control system will make wrong instructions on the operation of the compressor, humidification, and dehumidification systems. At present, most air-conditioning designs do not consider the impact of this situation on the air-conditioning system, because the time of this impact is shorter, and the system will reach normal operating conditions based on the new information in a shorter period of time, so there is no design for air separation. Although this effect is relatively small, we believe that in a demanding computer room, it is best not to let the system run incorrectly for a period of time, so we can artificially increase the air barrier for the air conditioning system.

7) Check whether the air pressure on the intake side of the computer and other equipment that needs cooling is normal, because with the relocation and increase of computer equipment, the increase in the cable under the floor may affect the air pressure of the air conditioning system, causing the computer and The static pressure of other equipment is not enough, which requires our equipment maintenance and management personnel to make corresponding adjustments to the air duct of the air conditioning system or add air conditioning equipment.

The above is the basic work we do when inspecting and maintaining the precision air conditioner in the computer room. It may be different in other computer rooms, because some steps need to be determined according to the condition and model of the equipment. At the same time, with the improvement of air conditioning equipment technology , Some steps do not need to be completed manually.